UTCIS-PT™ Update 19i

| Version # of this release | 19i | |

| Upgrade Method | Controller Wiring Modification & Controller Software Upgrade | |

| Controller Software Download | utcispt_19i.utupg | |

| Estimated Upgrade Time | 30 minutes | |

| Upgrade Procedure - Controller Wiring Modification | ||

| Remove RPM Sensor - this is no longer required. | ||

| Remove the UTCIS™ Controller module from its mounting. The billet aluminim valve body can stay in place. Remove the Controller's cover by removing the four silver screws. | ||

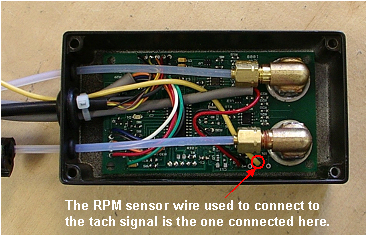

The tach signal input wire must be identified by looking at the Controller's Printed Circuit Board. The original RPM Sensor has two wires. The new configuration requires only a single wire. The correct

RPM sensor wire is the wire connected to the hole as shown in the photo below. The other RPM sensor wire is no longer used. Lengthen the correct wire using a bullet connector to reach the wire in the car which carries the tachometer signal.

Connect this wire to the tach signal. | ||

| Re-install the UTCIS™ controller cover then re-mount the controller. | ||

| Upgrade Procedure - Controller Software Upgrade | ||

| Follow the instructions in the UT Engine Management Software to upgrade the Controller software. A brief synopsis is presented here. | ||

| Connect your UT Engine Management Software to your UTCIS-PT™ unit. Select the Upgrade menu under the File | Advanced menu. You will be prompted for an upgrade file, browse to the utcispt_19i.utupg file on your computer hard drive. You will have an opportunity to confirm this step before your UTCIS-V™ is updated. | ||

| If you have questions on this modification, please contact UnwiredTools technical support at 928.773.0469 x 802 | ||

| Changes in this Revision | ||

| 1. Changed startup mode threshold to 0.2bar. The startup mode threshold waits for valid control pressure before the product starts regulating. In previous versions the startup mode threshold was 1.0bar. In previous versions if the control pressure was set below 1.0bar in warm-up mode and the warm-up mode was aborted before the control pressure reached 1bar then the product would stay in startup mode indefinitely and regulation of control pressure would never occur. | ||

| 2. The control loop response time was reduced from 100ms to 20ms | ||

| 3. The RPM Sensor was eliminated. The RPM input has been changed to use the tach signal. | ||

Support Email Address: support@unwiredtools.com

Support Telephone Number: 928.773.0469 x 802

Sales Telephone Number: 928.773.0469 x 801